Driving Innovation with 3D printing.

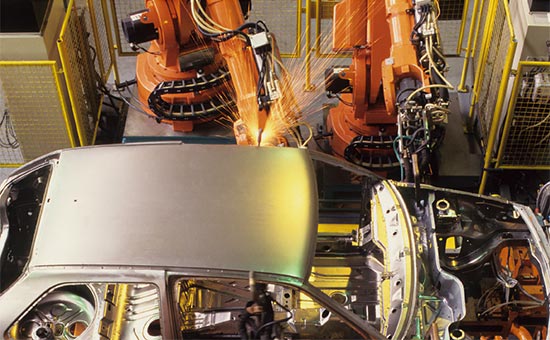

Turbocharged manufacturing.

In automotive manufacturing plants, 3D printing lowers tooling costs – with better designed, lighter tools reaching the line significantly faster. OEM’s and suppliers are investing in additive manufacturing to reduce cost, increase quality and, mostly importantly, save time.

Better tools. More efficient manufacturing.

3D printing helps you take control of tooling, optimize assembly, and boost factory floor performance. Build composite tools in a fraction of the time – ergonomically suited to the specific jobs, to increase productivity and improve safety for engineers. Avoid scrap and retooling by testing injection-molds and other tools before machining them.

Design better. Prototype faster.

3D printing gives your design team freedom to bring ideas to life without the time or financial constraints of traditional manufacturing. With your own 3D printer in-house, you can design and prototype rapidly. Find more ways to cut weight, improve functionality, or perfect a distinctive design – all in less time.

Better than traditional methods.

We’ve been working with our clients at Polaris for over 20 years, helping them advance their tooling capabilities and manufacturing processes so they can meet their customer’s needs faster, without sacrificing their cosmetic standards.